가스공급시설에 Filter Separator 또는 Coalescing filter 등으로 구성품이 있음. 동일한 목적으로 보이는 기기지만

다양한 형태로 분류, 이름이 있고 명확하게 정의된 것이 없어서 인터넷 사이트에서 모아봄

- Filteration필터링은 이물질을 제거하는 것이고, 이를 필터에 가두어 더 이상 기기를 통과하지 못하는 것이다.

- Separation은 Gas-Liquid (or Liquid-Liquid)에서 Liquid(water, hydrocarbon) 를 분리해 내는 것이다.

이 기능을 위해서 Gas supply쪽에서는 다음 2가지 방법이 주로 사용되는데

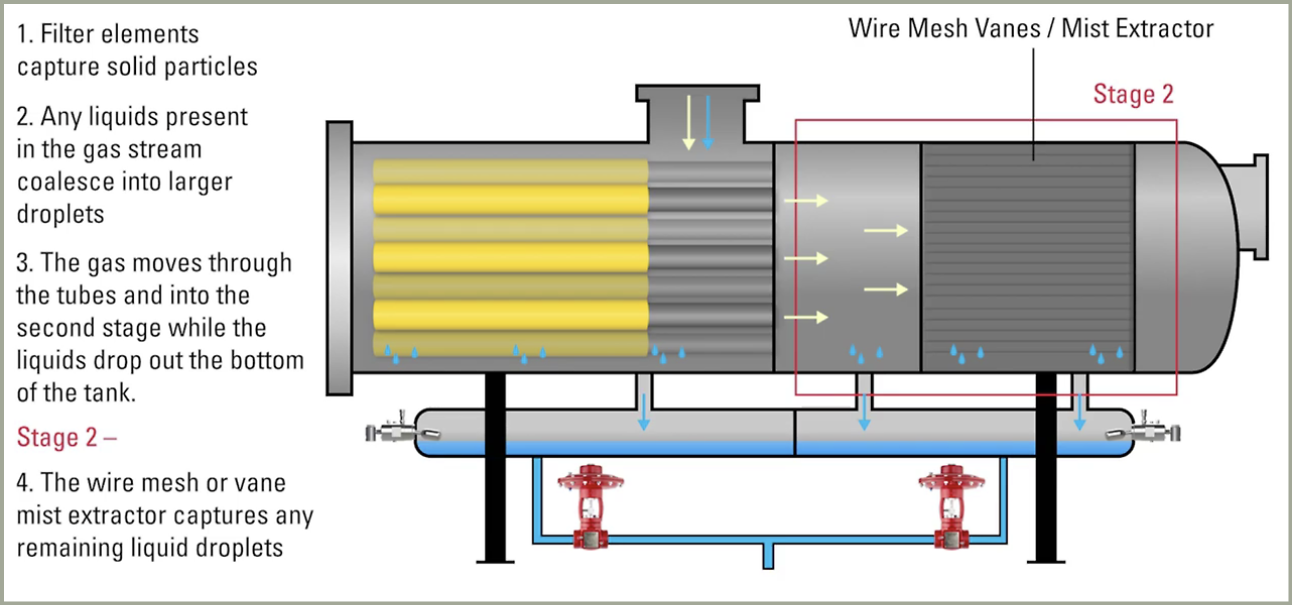

1) Mist Eliminator >> 격벽을 통해 분리해 내거나 Gas-Liquid일 때는 상분리

2) Coalescing >> 일종의 흡착과정을 일으키는 Colescaing Filter를 사용한 분리가 있다

>> 그래서 목적은 Separation이지만 그 수단을 표기하는 경우에는 경계가 애매해 진다.

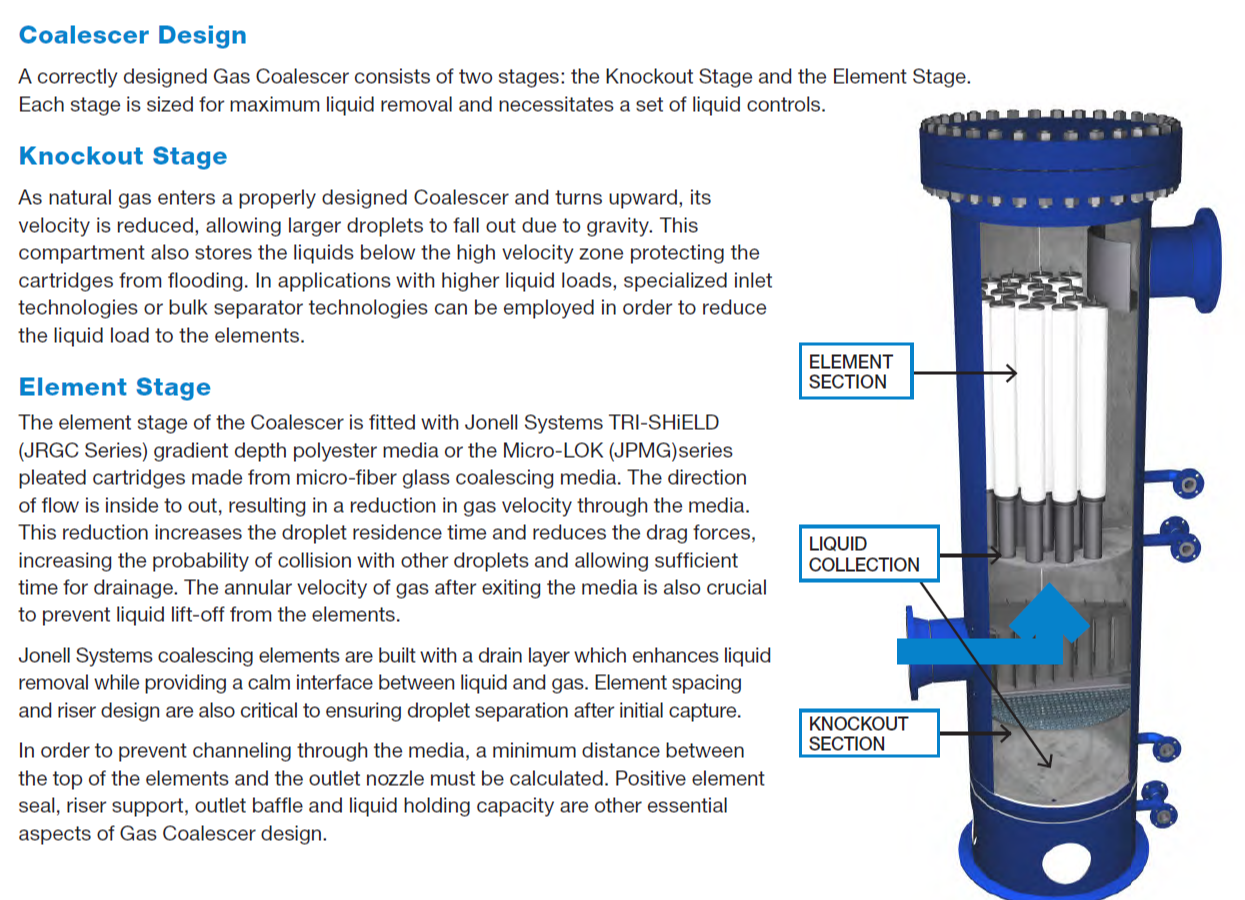

Coalescing filter를 사용한 Separation을 담당하는 기기는 Filter Separator라고 부르고,

Coalescing FILTER 이기 때문에 이물질 제거Filteration도 같이 하게 된다

** 관련기자재 공급 회사마다 Filter , Separator의 개념이 다르게 설명하고 있으니 다른 자료들 참고도 필요함

샘플1)

가스관련 공급사 kimaray.com의 홈페이지에 자세한 설명이 있다.

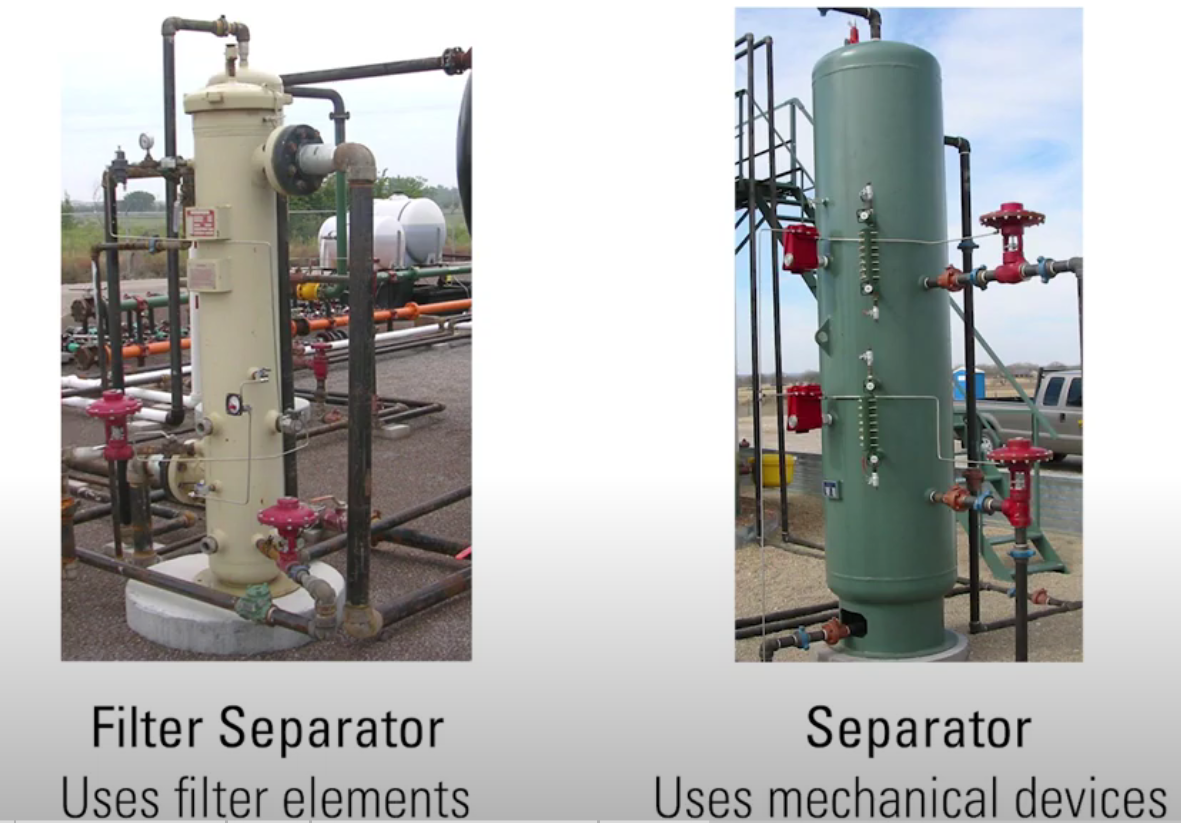

- Separator와 Filter Separator의 차이를 명확히 구분해 두었고

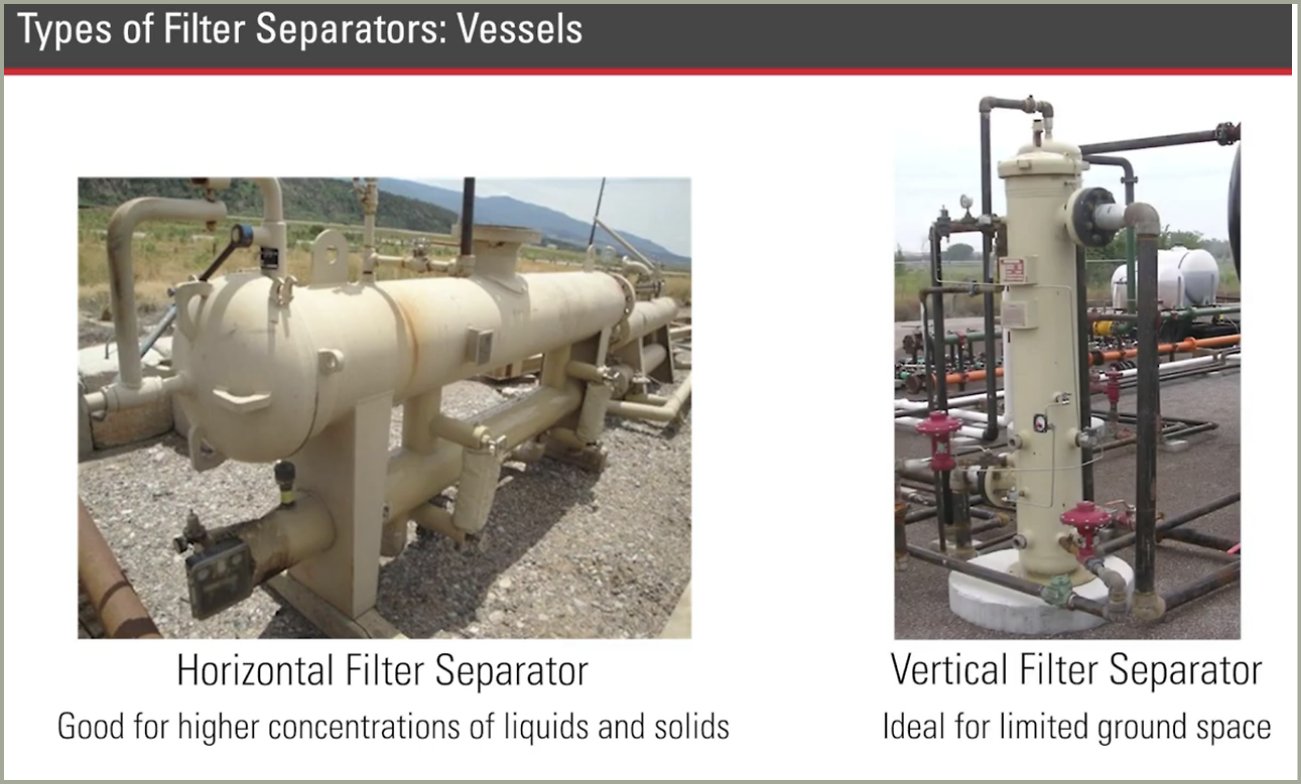

- 여기서 Filter Separator의 Horizontal , Vertical type에 대해서 2가지의 기능은 동일하나 용량과 면적으로 사용처가 정해진다 언급한다.

https://kimray.com/training/what-filter-separator

What is a Filter Separator? | Kimray

Kyle Andrews Kyle Andrews serves as Product and Applications Trainer at Kimray. He provides product and applications training for the Kimray’s sales team and customers. More by Kyle

kimray.com

Filter Separator vs Separator

; (Colescing filter)필터를 통한 water droplet 제거를 하면 Filter Separator

비중차이를 통한 분리는 Separator라고 명칭

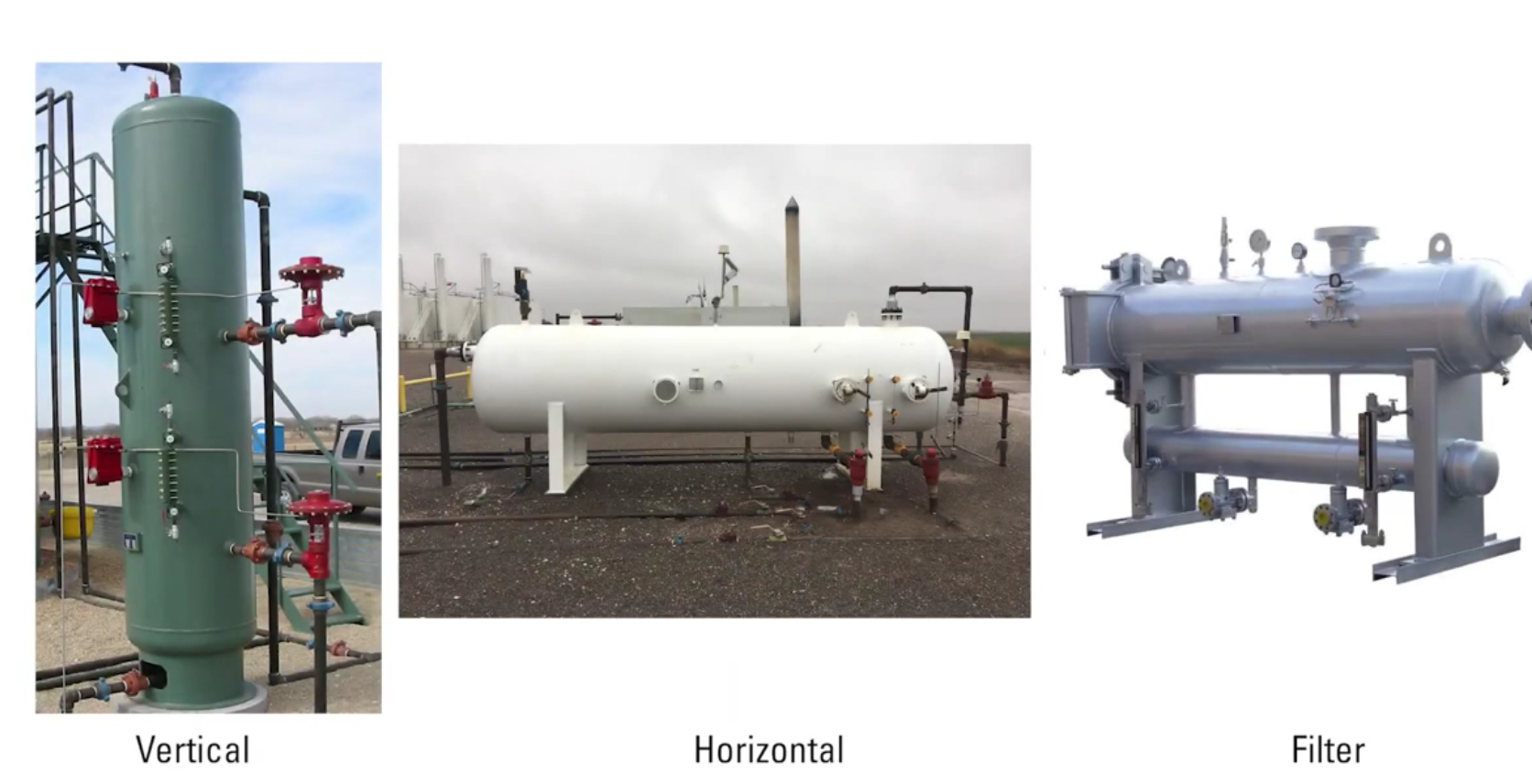

Type of Separator

; Separator의 3가지 타입에 대해서 구분

Filter Separator의 가로형 / 세로형

; 대용량 처리에 가로형이 좋지만, 공간 제약이 있을 때는 세로형

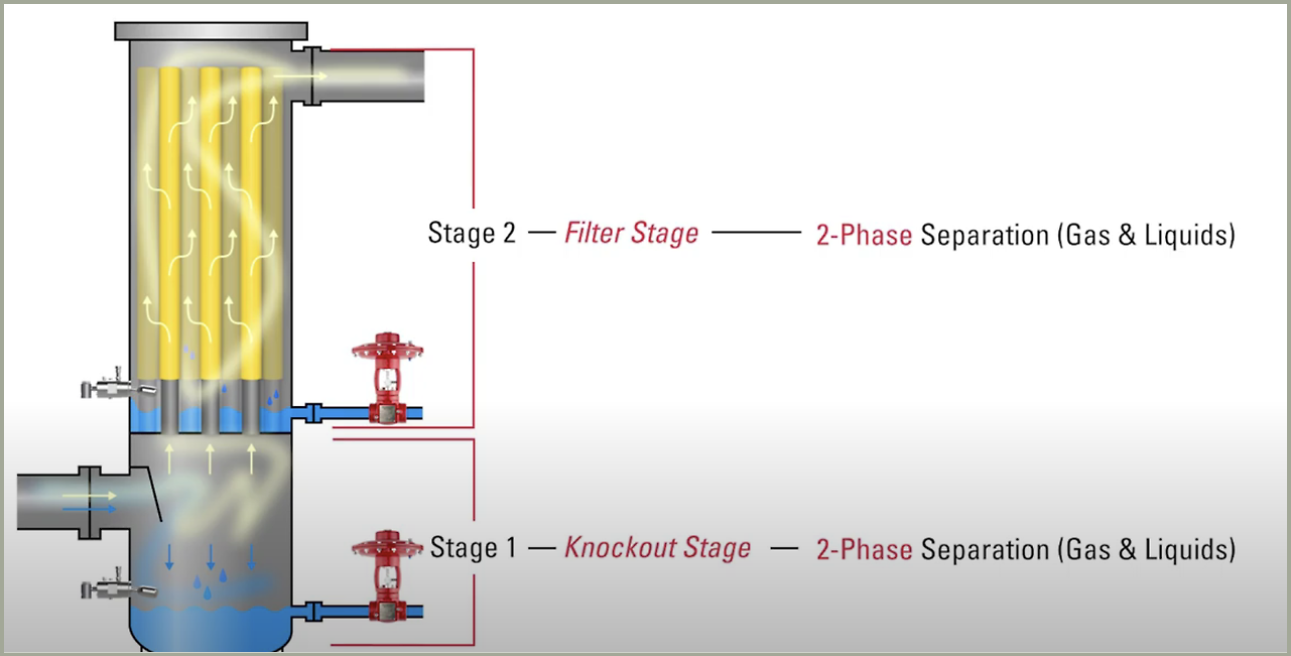

Filter Separator의 가로형 / 세로형의 내부처리 과정

샘플2)

https://www.hcpetroleum.hk/wap/product-detail/filter-separator

Filter Separator

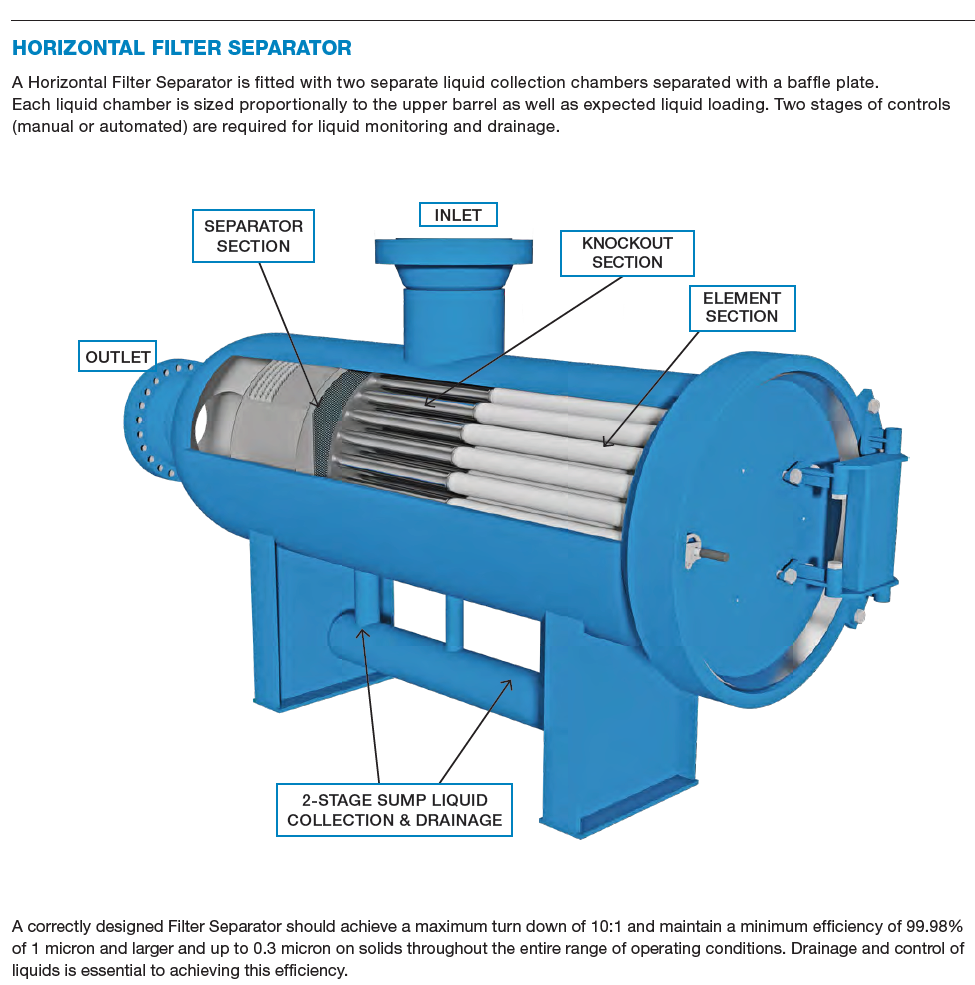

Filter Separator is used to remove liquid, small solids (created by the tubing and wing erosion) and other particles from the flow steam. Filter separators, like other gas-liquid separators, can be horizontal and vertical; the most common type is horizontal. If there is a large amount of water in coming gas, structure of filter separator is designed to have a “boot” in the bottom of the separator connected with two similar tubes parallel to each other. Retention period required between 3 and 5 minutes for hydrocarbon (oil)-water separation by settling. Sizing the dimension of the filter separator’s each section depends on the calculations and design of manufacturer or engineering company.

Filter separator consist of coalescing filters and mist extractor inside of its vessel, usually have quick opening closures for maintenance and replacement of the filters.

"Filter separators and coalescing filters are required, when droplet sizes below 3 microns."

Filter separators have a wide application in gas pipelines, as well as the gas processing plants, for example, acid removal units, when after passing filters separators catch the liquids and condensed hydrocarbons coming from the absorber. In gas processing, adequate inlet separator and filter separator are required to prevent foaming due to the chemical contamination. If absorber is downstream from amine unit, glycol unit, or compressor, a filter separator is required. Also, filter separator and coalescing filter used to prevent fine mists from entering the absorber.

Solid removal efficiency of the filter separator is

- 100% when size of solids is 3 microns & larger, and

- 99%, when size of solids are 0.5-3 microns,

- while liquid removal efficiency is 98% when size is 8 microns & larger.

Efficiency of filter separator depends on particle size, distribution of particles, and liquid loading.

Gas-liquid and Liquid-Liquid Coalescers

Coalescers are used for gas-liquid or liquid-liquid separation. Coalescers are designed by the composition and type of contaminants on the flow media.

Coalescing filters are also used to prevent fine mists from entering the absorber. Liquid-gas coalesces are also used for removal of fine aerosols in gas production, processing and transmission. Coalesce cartridges, made of pleated glass fiber media supported by metal core, which has higher efficiency then traditional separators with mesh pads and vane packs. The reason is higher efficiency is that cartridges contain a much finer pore structure and larger surface area. Coalescers remove 99.5% solids 0.4 micron and larger.

"Iron Sulfide from corrosion, can interfere with the liquid-liquid separation, thus the section of liquid collection acts as a holder for the liquids removed from the gas in the vessel upper sections"

Coalescing Filters, normally are vertical, used in natural gas pipelines to remove liquids from the flow streams, where very high gas-to-liquid ratios. Coalescing filters have only filter cartridges.

샘플3)

https://www.jonellsystems.com/resources/application-solutions-matrix/

_